Handheld Laser Measuring Tools are not enough

Carpenters and furniture makers have always relied on traditional tools such as:

– tape measure

– folding ruler

– telescopic ruler

– handheld laser distance meter

While these tools are useful, they fail when it comes to one of the biggest challenges in carpentry: measuring wall angles. A telescopic ruler may provide stable lengths, but it cannot deliver the precision that modern laser measuring tools offer.

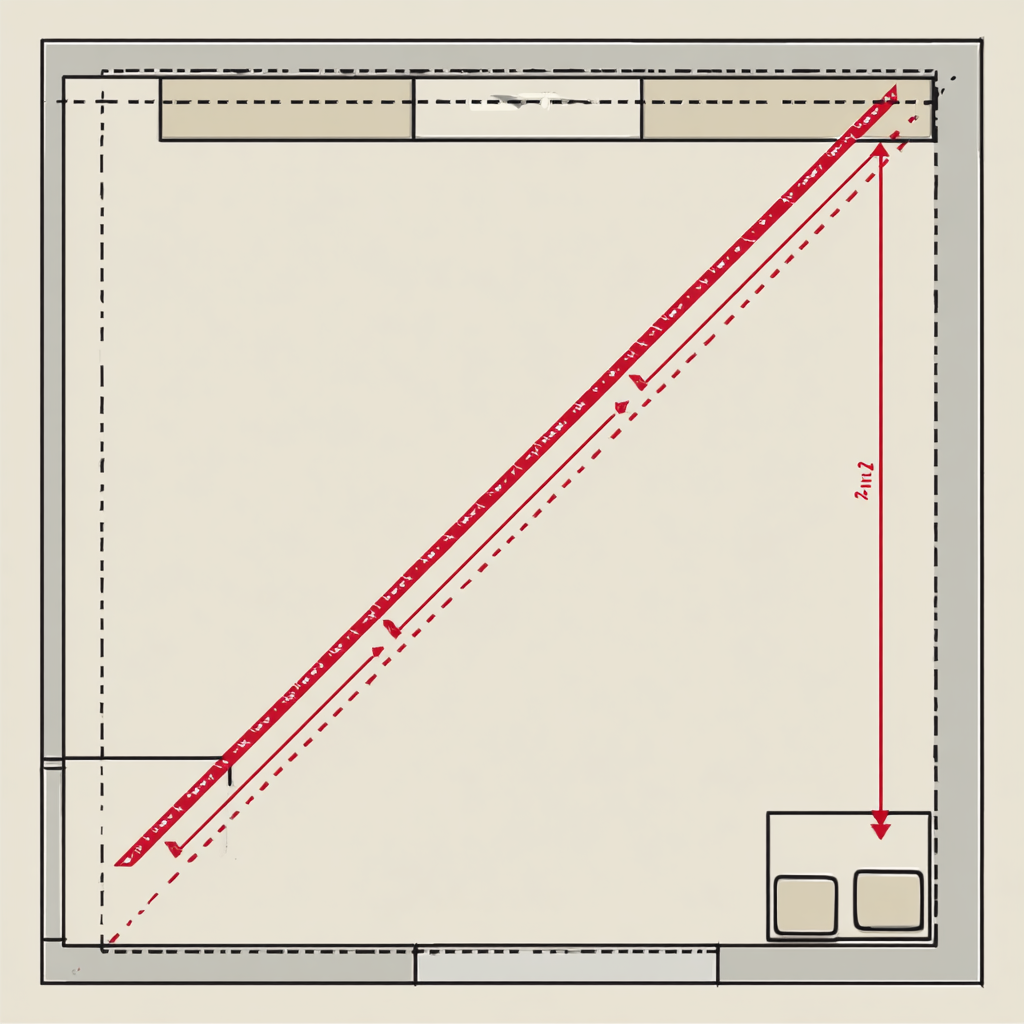

The challenge with wall angles

In real houses, walls are rarely straight or perfectly square. They often bulge or curve. Using a large protractor on such surfaces leads to errors. Even a huge 2x2m protractor is:

– hard to handle

– requires two people

– blocked by obstacles like beams in the corner

For carpenters, this means wrong dimensions, wasted material, and costly corrections. This is why laser measuring tools are becoming essential.

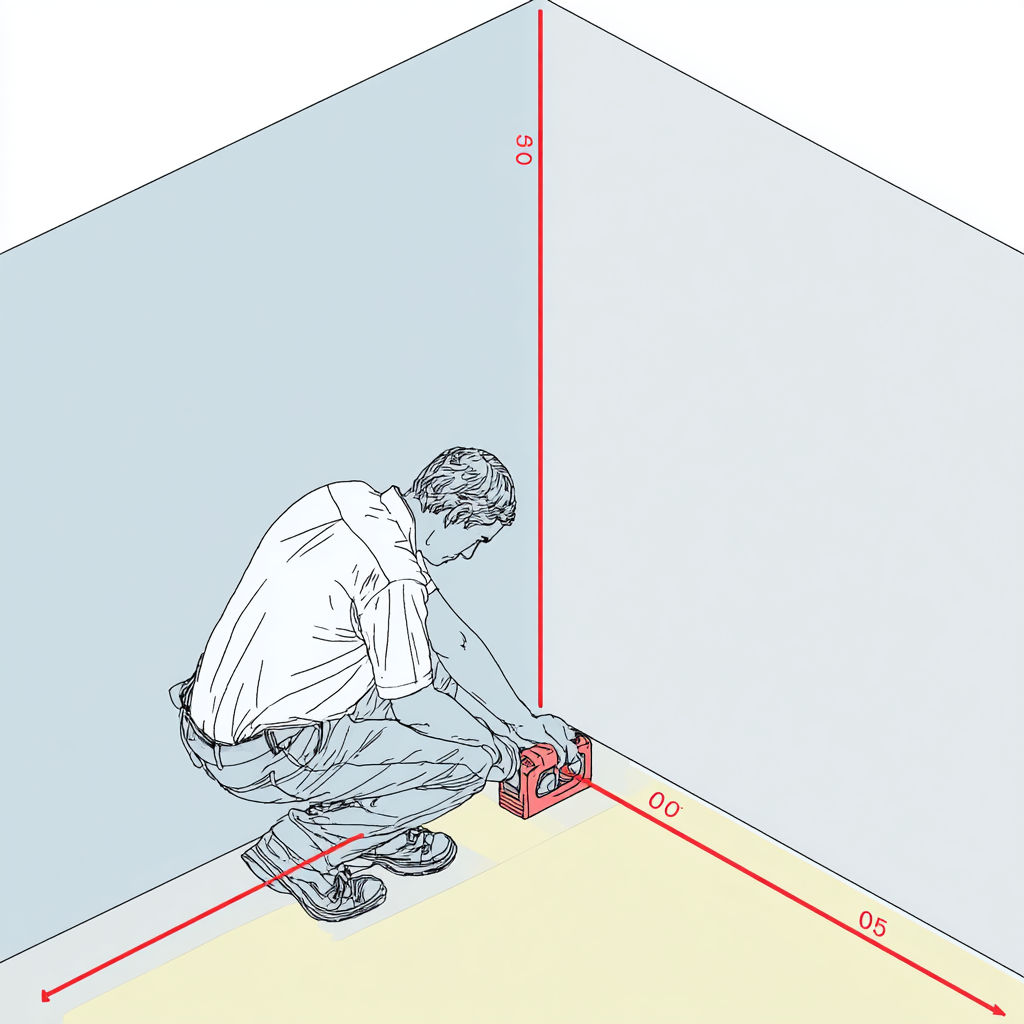

Laser Measuring with cross line lasers

A common laser measuring tool is the cross line laser, projecting two lines at 90°. By measuring the distance of the laser lines from the wall every meter, a carpenter can estimate the angle. But this method is:

– slow

– experience-based

– prone to human error

It helps, but it’s far from accurate laser measuring for carpenters.

Photogrammetry and LiDAR – not for woodworking

Apps based on photogrammetry or LiDAR are popular among architects. But for carpentry they are not reliable because they:

– have large measurement deviations

– lack millimeter precision

– are impractical for everyday furniture making

They may look advanced, but they cannot replace professional laser measuring tools designed for carpenters.

Manual 3D laser tools – partial solutions

There are also hand-operated 3D laser tools that rotate manually, point by point. They can build a 3D representation, but:

– bulging plaster gives wrong results

– they struggle with curves

– they are slow and complex to set up

They work in theory, but in practice they are not efficient for carpenters who need fast and accurate laser measuring tools.

High-end 3D scanners – too much for carpentry

Professional 3D scanners can capture every detail, but:

– they cost tens of thousands

– they generate massive files

– they require an operator

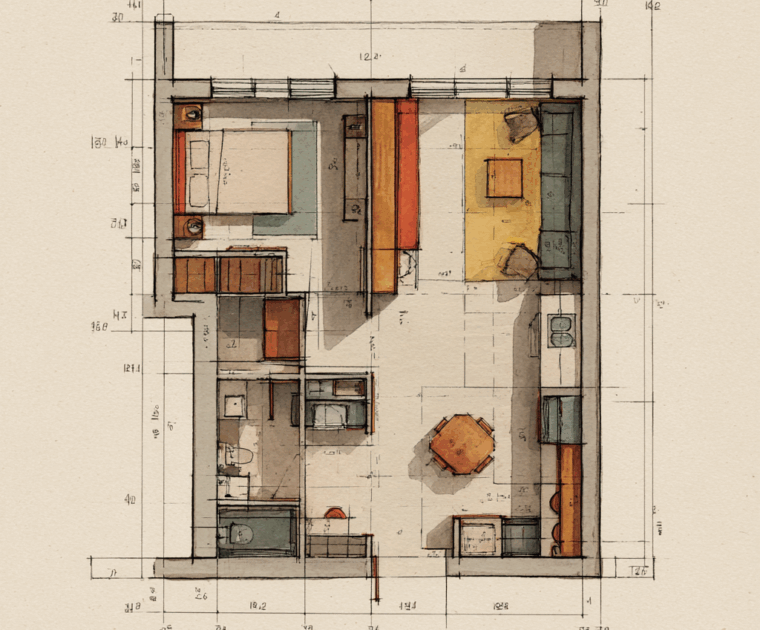

For most furniture makers, these tools are overkill. What’s really needed is a two-dimensional cross-section, delivered by a simple and reliable laser measuring tool.

Laser Measuring with the practical solution: the 2D Scanner

The 2D Scanner is a dedicated laser measuring tool made for carpenters:

– lightweight and portable

– millimeter accuracy

– easy to use

– affordable compared to 3D systems

Real-world benefit

Traditionally, a carpenter visits the client twice – once for initial measurements and again after removing the old kitchen. With the 2D Scanner, the carpenter can ship the tool to the client, who scans the room easily and sends back the data. This avoids a second trip and saves time and costs.

Why accuracy matters in carpentry

A few millimeters off can mean:

– panels that don’t fit

– wasted material

– delays on site

Generic imports or cheap tools cannot meet this demand. Professional laser measuring tools like the 2D Scanner guarantee precision.

Conclusion

For carpenters, laser measuring tools are not a luxury – they are a necessity.

The 2D Scanner combines:

– precision

– reliability

– simplicity

– affordability

It is the laser measuring tool that truly meets the needs of carpenters and furniture makers.

Learn more

Learn more about the 2D Scanner on our website, explore our YouTube channel for live demonstrations, or check our Frequently Asked Questions for details.

Our vision is clear: to give carpenters the right laser measuring tools that make their work easier, faster, and more accurate.